Dear Backers,

We are very happy to announce some major updates and news regarding our successful Kickstarter campaign. We've made significant progress in preparing for the production of ChromaSet products through adjustments with our partners. While we have some unfortunate news about a delay, we are excited to share remarkable developments, especially regarding our key product, ChromaHead.

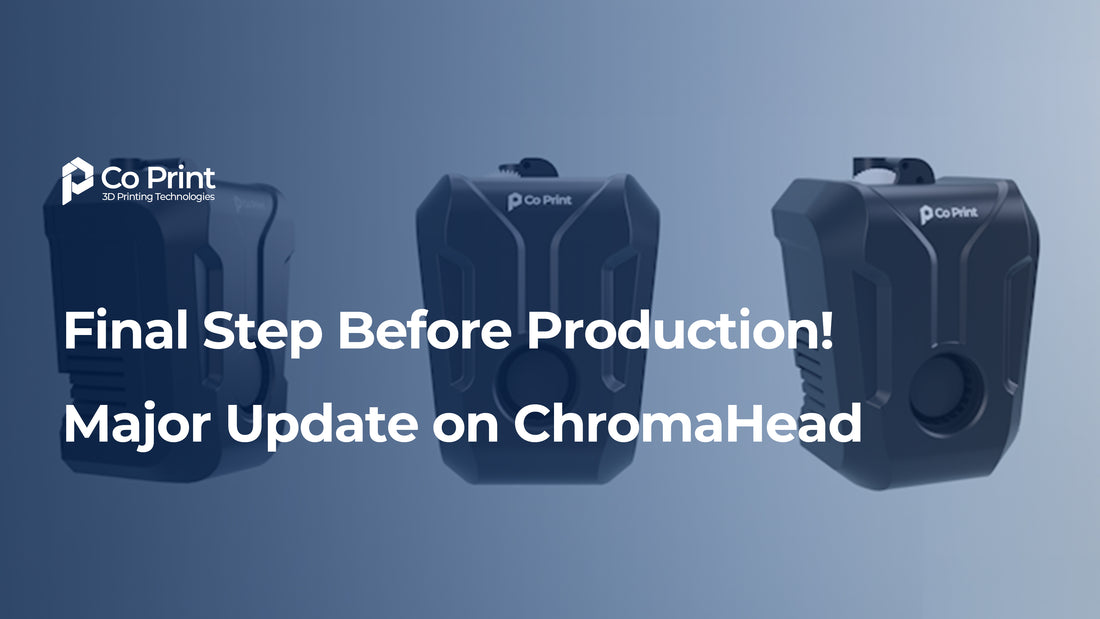

As the final step before production, we've implemented improvements on ChromaHead, making it smaller, lighter, and more stable. We take pride in sharing the details of the new ChromaHead with you.

Size Reduction and Enhanced Functionality

- The extruder motor inside ChromaHead has been replaced with a pancake motor, and the extruder mechanism has been downsized.

- Instead of the BL-touch table calibration sensor, a smaller and more precise proximity sensor has been adopted, increasing accuracy while reducing size.

- The servo motor used for filament cutting has been replaced with a specially designed mechanism, increasing the performance while reducing weight.

- Cooling system fan positions and air channels have been optimized, minimizing size and enhancing performance.

- The ChromaHead control board has been redesigned with a two-layer structure, saving space.

In the light of those revises, we are happy to announce that we have accomplished 30% reduction in size compared to the previous version while increasing the performance.

Exterior Design Redesigned

- Staying true to the Series II product family concept, the design has been refined by transitioning from the previous rectangular form to a sleeker, downward-tapered look with sharp lines, achieving a more minimalist and aesthetic design.

30% Weight Reduction

- Through the redesign of the extruder, filament cutting mechanism, and overall compact design, the new ChromaHead model is now 30% lighter than the initial version.

Improved Filament Cutting Mechanism

- Our extensive filament cutting tests have led to the optimization of the cutting mechanism and enhancing stability.

- The cutting blade was prevented from oscillating by bedding.

- By switching to the gear system, the space occupied by the mechanism became more compact and its weight was reduced.

Increased Usable Area on Print and Calibration Precision

- ChromaHead avoids print bed area loss in most of the 3D printers. However, with ChromaHead v2.0, losses in machines like the Ender 3v2 have been completely eliminated, and losses in certain printers like Creality K1 have been significantly reduced.

- With the changes made in the positioning of the hotend and the dimensions of ChromaHead, space losses that were experienced in some printers (e.g., Ender 3v2) have been prevented.

- Scaling in the visual was based on the Creality K1, and ChromaHead can be used in most CoreXY printers without experiencing any bed loss.

Updates and Performance Improvements in ChromaScreen Software

Based on user tests and feedback, we've updated and improved ChromaScreen software.

Changes include:

- Introduction of a system feedback connection when no printer is connected or an error occurs for issue resolution.

- Transitioned to a tab-based structure on the Dashboard page. This new tab layout brings users together with three different controls. Through tabs, you can view your 3D printing statistics, examine system data, and perform multiple filament controls. This allows for easy viewing of many indicators without changing pages.

With the updates regarding the tabs we have made significant improvement in user experience.

- The setup wizard is now much faster. You can easily select your printer and complete the installation by loading preset configurations, eliminating the need to input printer specifications.

Advanced ChromaSet Control Boards

- ChromaControl, a new control board designed for ChromaHead, utilizes an STM32 microcontroller for efficient component control. Adjustments have been made with the internal MCU to minimize transmission losses, transforming it into an easy-to-use and user-friendly structure.

- As a solution to the difficulties in using the 24-pin straight connector on ChromaHead and reliability issues, a completely new system has been adopted. For this purpose, the CAN Bus communication protocol has been chosen, and a new card has been designed. Use of CAN Bus aims to reduce communication losses between ChromaHead and ChromaPad. Since the communication cable in large 3D printers is longer than standard, CAN Bus will provide lossless and seamless communication.

- We offer the integration of an accelerometer into the control board, bringing the Input Shaping feature directly into ChromaHead for your use. You can calibrate both the X and Y axes for your CoreXY printers. For Bed Slinger printers, you can utilize the accelerometer inside ChromaHead for the X-axis and use the slot in ChromaPad for the Y-axis

- Updates have been made to the ChromaPad Motor driver section, transitioning to a more suitable design. The thickness has been reduced, altering the placement inside the casing. To prevent excessive heat issues within the casing, a fan has been added. The power supply design has been modified to enable usage with 12-24V. With the use of CAN Bus, the Master MCU has been upgraded, allowing for a transition to a higher model.

Mold and Electronic Board Production

- Besides ChromaHead changes, molds, and electronic board designs for other products have been finalized. After final checks with suppliers, mass production is set to begin this month.

- After the successful completion of the long-term tests of ChromaHead, its production will also commence shortly.

New Contents Coming Shortly

We carefully reviewed the responses you provided to our survey regarding the printers you will use with ChromaSet and KCM Set products. Based on the results we obtained from this survey, we will prepare video and written content covering installation, usage, and some enhancements for the most commonly used printers. Starting from May, we will begin publishing the content we have prepared, ensuring that you are well-prepared to use the products most effectively once they are delivered. We will continue to create these supportive materials regularly, taking into account the requests received from you.

Unfortunately, a delay :(

Due to all these improvements, we anticipate a delay in the possible deliveries to May. We are sorry to tell you about this delay. To minimize potential delays in production, we continue to expand our team. We appreciate your understanding of this, and we want you to know that our team is working hard to provide the best solution for you, which is why there is a delay.

The ChromaSet product family has been developed based on usage tests and feedback, and it is now much more effective. As we are about to start mass production, usage, durability, and software tests are still ongoing. We are dedicated to delivering a flawless and user-friendly product to our valued users. We will continue to keep you updated on developments. During this time, you can reach out with any questions via Kickstarter or info@coprint3d.com.

Stay tuned for new updates!